à¤à¤®à¤ªà¥à¤à¤ बà¥à¤à¤ यà¥à¤¨à¤¿à¤

à¤à¤®à¤ªà¥à¤à¤ बà¥à¤à¤ यà¥à¤¨à¤¿à¤ Specification

- वज़न

- किलोग्राम (kg)

- एप्लीकेशन

- For Industrial Purpose

- मटेरियल

- Steel

- रंग

- White And Sky Blue

- बिजली की आपूर्ति

- Electricity

- कंट्रोल मोड

- Manual

à¤à¤®à¤ªà¥à¤à¤ बà¥à¤à¤ यà¥à¤¨à¤¿à¤ Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- टेलीग्राफिक ट्रांसफर (T/T), चेक

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About à¤à¤®à¤ªà¥à¤à¤ बà¥à¤à¤ यà¥à¤¨à¤¿à¤

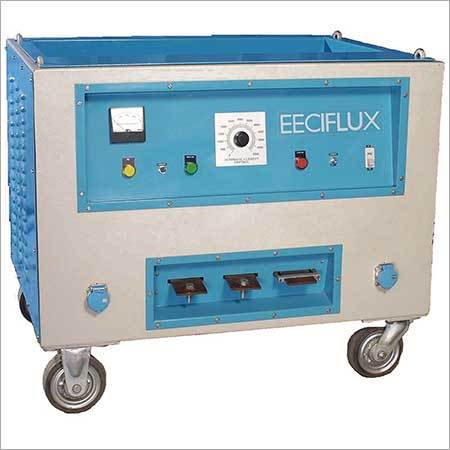

Mpi Bench Unit which is commonly referred as magnetic particle inspection bench unit is used to generate powerful field of magnetism to test different sorts of machine parts. Notable for its compact shape, this machine can easily integrate with different testing environment. The ergonomic design of its lever driven clamping system enables this bench unit to hold machine components firmly between its copper fabricated gauze pads. The user of this machine can easily interchange its pads or can dissemble these pads. We are a prestigious supplier and manufacturer of excellent grade Mpi Bench Unit.

Features

- Long working life

- Easy to comprehend operation

- Precise dimension

- Easy to install

Air supply | 5 Kg / cm2 FRL |

Tank Capacity | 40 Liters |

Part Weight Capacity | 80-90 Kgs. |

Part Length Capacity | 1750 mm |

Output Ports | 2 ports,230V,50 Hz |

Net Weight | 850 Kgs |

Input Supply | 415 V,50 Hz,2 Phase |

Input Current | 135 Amps |

Duty Cycle | 0.5 sec ON 5 sec OFF |

Dimension without Hood | 1850(L)x940(W)x1780(H) |

Coil Diameter | 300 mm |

Superior Construction and Reliable Performance

Crafted from high-quality steel, the MPI Bench Unit offers exceptional durability and sturdiness, making it suitable for heavy-duty industrial use. The manual control system allows for hands-on management, ensuring adaptability and precision during operation. Engineered for dependability, its design prioritizes both functionality and operational ease.

Distinctive Design and Practical Features

This bench unit stands out with its appealing white and sky blue finish, reflecting both style and professionalism in industrial settings. Weighing 850 kg, it provides a stable platform for various industrial tasks. The electric power supply ensures consistent performance, supporting the diverse needs of manufacturing environments.

FAQs of Mpi Bench Unit:

Q: How is the MPI Bench Unit installed and set up in an industrial environment?

A: The MPI Bench Unit should be situated on a stable, level surface due to its considerable weight of 850 kg. Electrical connections must be configured in accordance with industry safety standards. Setup typically involves integrating the unit with the workflow, following manufacturer guidelines provided by the Indian supplier.Q: What industrial applications is the MPI Bench Unit suitable for?

A: This unit is designed for versatile use in manufacturing, quality control, and testing environments. Its steel construction and manual controls make it ideal for applications requiring robust, reliable equipment with hands-on operation.Q: When should maintenance be performed on the MPI Bench Unit?

A: Regular maintenance is recommended to preserve performance, typically every three to six months, depending on operational intensity. Maintenance includes checking electrical systems, mechanical integrity, and manual controls to ensure safe and efficient operation.Q: Where is the MPI Bench Unit manufactured and exported from?

A: The MPI Bench Unit is manufactured, supplied, and exported from India, with the producer serving as a reliable trader for international and domestic markets.Q: What is the process for operating the MPI Bench Unit manually?

A: Operating the unit involves powering it through an electric supply and using the manual control features to manage workflow. The control mode allows users to adjust settings directly, optimizing operation in real-time as per task requirements.Q: How does the material and design of the MPI Bench Unit benefit users?

A: Its steel construction ensures long-term durability and resistance to industrial wear, while the weight adds stability during operation. The white and sky blue finish contributes to a clean, professional look in any industrial setting.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in मोबाइल Power Type Unit Category

एमपीआई उपकरण

वोल्टेज : वोल्ट (v)

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 10

माप की इकाई : यूनिट/यूनिट

रंग : Sky Blue And White

मटेरियल : Steel

मोबाइल पावर टाइप उपकरण

वोल्टेज : वोल्ट (v)

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

अनुकूलित चुंबकीय कण परीक्षण मशीनें

वोल्टेज : वोल्ट (v)

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

रंग : White And Blue

मटेरियल : Metal

बेंच यूनिट

वोल्टेज : वोल्ट (v)

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : यूनिट/यूनिट

रंग : Blue and White

मटेरियल : Metal

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें