ठनà¥à¤à¥à¤²à¤¿à¤¤ à¤à¥à¤à¤¬à¤à¥à¤¯ à¤à¤£ परà¥à¤à¥à¤·à¤£ मशà¥à¤¨à¥à¤

ठनà¥à¤à¥à¤²à¤¿à¤¤ à¤à¥à¤à¤¬à¤à¥à¤¯ à¤à¤£ परà¥à¤à¥à¤·à¤£ मशà¥à¤¨à¥à¤ Specification

- आयाम (एल* डब्ल्यू* एच)

- मिलीमीटर (mm)

- तापमान

- सेल्सियस (oC)

- रंग

- White And Blue

- मटेरियल

- Metal

- वोल्टेज

- वोल्ट (v)

ठनà¥à¤à¥à¤²à¤¿à¤¤ à¤à¥à¤à¤¬à¤à¥à¤¯ à¤à¤£ परà¥à¤à¥à¤·à¤£ मशà¥à¤¨à¥à¤ Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- टेलीग्राफिक ट्रांसफर (T/T), चेक

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About ठनà¥à¤à¥à¤²à¤¿à¤¤ à¤à¥à¤à¤¬à¤à¥à¤¯ à¤à¤£ परà¥à¤à¥à¤·à¤£ मशà¥à¤¨à¥à¤

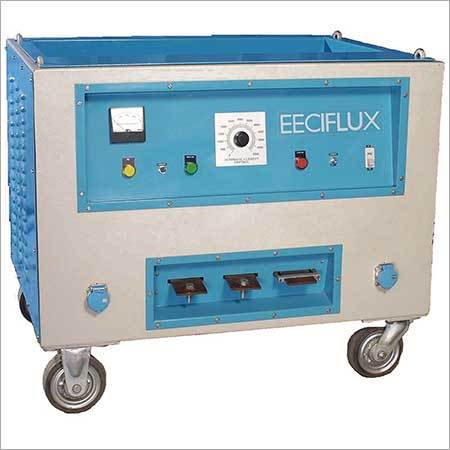

Designed to suit different industrial application needs, the offered Customized Magnetic Particle Testing Machines are appreciated for their high working efficiency. These testing machines are wonderful options to identify fracture appeared on iron and steel fabricated parts. These are equipped with advanced field cable connector, AC field, DC field and required cables. High sensitivity level, long working life, user friendly mechanism and reasonable price are the key attributes of these machines. We are an eminent manufacturer and exporter of Magnetic Particle Testing Machines.

Features

- Long service life

- Application specific design

- Energy efficient operation

- Affordable price

Technical specification

Air Supply | 5 kg / cm2 FRL |

Tank Capacity | 40 Liters |

Part Weight Capacity | 80 - 90 kgs |

Part Length Capacity | 1750 mm |

Output Ports | 2 ports, 120 V, 50 Hz |

Net Weight | 850 kgs |

Input Supply | 415 V, 50 Hz, 2 Phase |

Input Current | 135 Amps |

Duty Cycle | 0.5 sec ON 5 sec OFF |

Dimension without Hood | 1850 (L) x 940 (W) x 1780 (H) |

Coil Diameter | 300 mm |

Advanced Non-Destructive Testing

Our machines utilize magnetic particle testing to reveal flaws such as cracks in metallic components without causing damage. This reliable method helps maintain the highest safety and quality assurance standards across industries including automotive, construction, and manufacturing.

Customisation and Versatility

Engineered to fit specific client requirements, our testing machines can be adapted for various component sizes and testing parameters. Their robust metal construction and compact dimensions make them appropriate for both laboratory and onsite applications, enhancing flexibility and workflow efficiency.

FAQs of Customised Magnetic Particle Testing Machines:

Q: How do you operate the Customised Magnetic Particle Testing Machine?

A: To operate the machine, place the metallic component between the magnetic poles, apply the required voltage (240V), and introduce magnetic particles. The machine detects imperfections by highlighting magnetic leakage fields, allowing visual identification of flaws.Q: What materials can be tested using this machine?

A: This device is designed for magnetic particle inspection of ferromagnetic metals. It is particularly effective on steel and iron components, ensuring optimal defect detection on a range of metallic parts.Q: When is magnetic particle testing most beneficial?

A: Magnetic particle testing is especially beneficial during routine maintenance, production quality control, or final product inspections. It enables early detection of surface and sub-surface defects that could compromise integrity.Q: Where can these machines be utilized?

A: These machines can be used in industrial environments such as manufacturing plants, automotive workshops, laboratories, and construction sites across India and abroad thanks to our export capabilities.Q: What is the process involved with this testing machine?

A: The process involves magnetizing the metal part, applying magnetic particles, and observing for patterns indicating defects. Any cracks or discontinuities will attract particles, making them visible under suitable lighting conditions.Q: How does this machine benefit your business operations?

A: By delivering swift and accurate defect detection, these machines reduce downtime, promote higher quality assurance, and help avoid costly failures. Their customizable features ensure adaptability to specific operational needs.Q: Who can purchase these machines from you?

A: We serve a diverse clientele as an exporter, manufacturer, supplier, and trader in India. Businesses locally and internationally can contact us for tailored magnetic particle testing equipment solutions.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in मोबाइल Power Type Unit Category

एमपीआई उपकरण

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 10

वोल्टेज : वोल्ट (v)

मटेरियल : Steel

रंग : Sky Blue And White

मोबाइल पावर टाइप उपकरण

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

वोल्टेज : वोल्ट (v)

एमपीआई मोबाइल यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

वोल्टेज : वोल्ट (v)

मटेरियल : Steel

रंग : Sky Blue And White

बेंच यूनिट

माप की इकाई : यूनिट/यूनिट

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

वोल्टेज : वोल्ट (v)

मटेरियल : Metal

रंग : Blue and White

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें