Statovision - Eddy Current Software For Brake disc testing

MOQ : 1 Unit

Statovision - Eddy Current Software For Brake disc testing Specification

- Color

- Black

- Product Type

- Statovision - Eddy Current Software For Brake disc testing

- Usage

- Industrial

- Voltage

- 220 Volt (v)

- Power Supply

- Electric

- Application

- Industrial

- Display Type

- Digital

- Material

- Metal

Statovision - Eddy Current Software For Brake disc testing Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Day

- Delivery Time

- 7 Days

About Statovision - Eddy Current Software For Brake disc testing

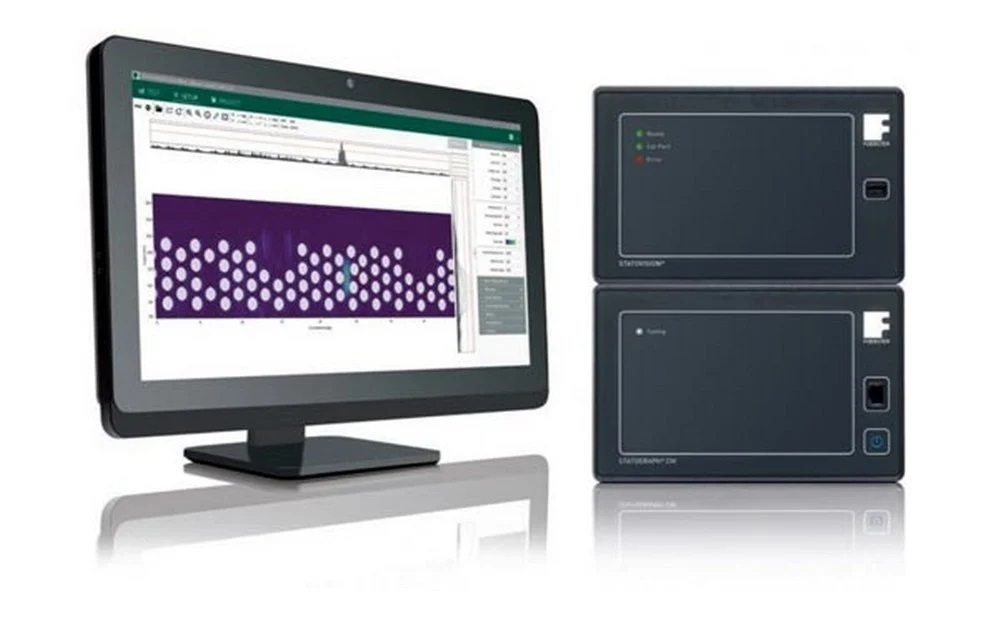

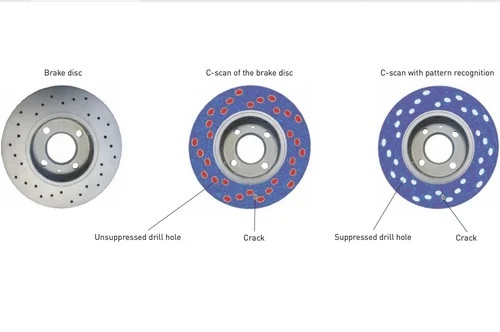

New dimensions in component testing With STATOVISION, FOERSTER offers an innovative software solution for the identification and visualization of heretofore undetectable errors. Intelligent filter algorithms enable previously impossible inspection tasks; since this allows interference signals to be filtered out and suppressed, cracks near drill holes or millings, for example, can be found. Furthermore, by superimposing the images of several components, it is possible to identify at an early stage patterns in the defects, e.g. due to tool wear, so that the source of the error can be eliminated.Advance Features:

- Intelligent filter algorithms for targeted suppression of interfering contours like drill holes, grooves, bevels, etc.

- High-resolution representation of the component surface

- Digital filters with large dynamic range

- Post-data analysis for process improvement, since raw data can be stored and post-processed

- Report creation in PDF, PNG and CSV formats

Advanced Brake Disc Evaluation

Statovision provides accurate, non-destructive testing for brake discs using eddy current technology. This advanced digital software is compatible with a variety of industrial setups and facilitates early fault detection, minimizing operational risks.

Designed for Industrial Applications

Built to withstand rigorous industrial environments, Statovisions software features a durable metal construction and a clear, digital display for real-time results. Its compatibility with standard 220V electric power makes installation straightforward in most factory settings.

Reliable German Engineering

Developed and produced in Germany, Statovision offers exceptional reliability and longevity. As a trusted exporter, manufacturer, and supplier, Statovision delivers consistent performance tailored to global industrial requirements.

FAQs of Statovision - Eddy Current Software For Brake disc testing:

Q: How does Statovisions Eddy Current Software perform brake disc testing?

A: Statovision employs eddy current technology to assess brake discs for surface and subsurface flaws without causing damage. The digital display presents instant results, enabling quick and accurate analysis.Q: What are the main benefits of using Statovision in industrial environments?

A: Statovision enhances testing efficiency, accuracy, and safety. Its non-destructive approach preserves valuable components, streamlines testing processes, and helps identify potential issues before they escalate.Q: When should this software be utilized in the brake disc manufacturing process?

A: Statovision can be incorporated during various production stages, particularly for final quality control checks or periodic maintenance routines, to ensure consistent product quality.Q: Where is Statovisions Eddy Current Software typically used?

A: Statovision is widely used in industrial facilities, manufacturing plants, and quality assurance laboratories that focus on brake component production and inspection.Q: What is the installation process for Statovision, and what are the power requirements?

A: Installation is straightforward and involves connecting to a 220 Volt electric supply. The software is compatible with standard industrial electrical systems and includes user-friendly interface for easy setup.Q: How do users benefit from the digital display feature?

A: The clear, black digital display allows users to monitor test results in real-time, ensuring accurate interpretation and swift decision-making, which is critical in industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Our Export Countries:

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry