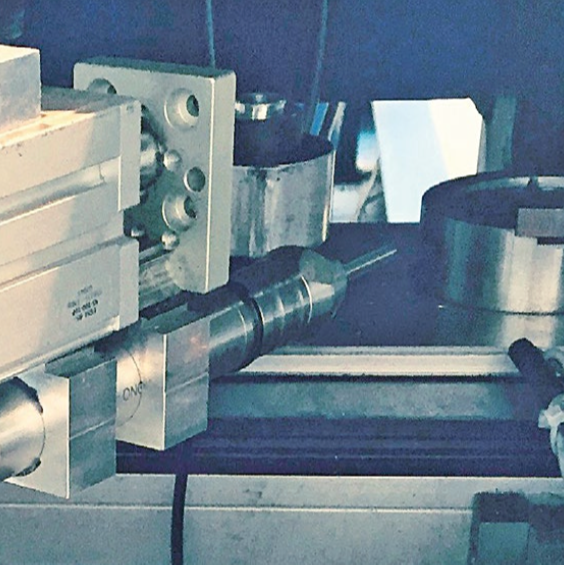

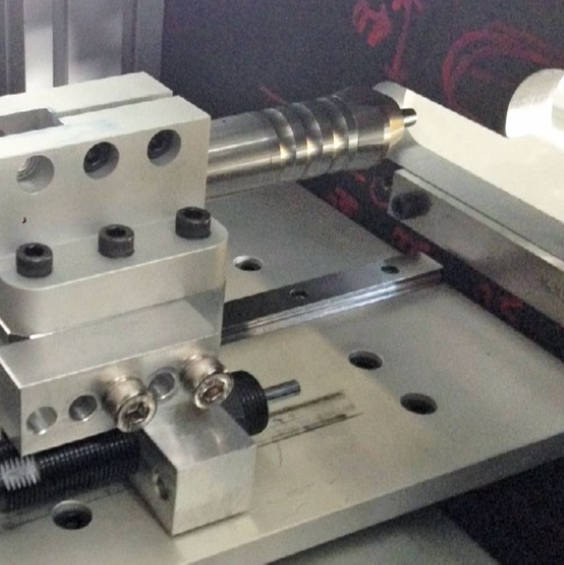

SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines

SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines Specification

- Application

- Industrial

- Voltage

- 220 Volt (v)

- Weight

- 3400 Grams (g)

- Power Supply

- Electric

- Usage

- Industrial

- Color

- Grey

- Product Type

- SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines

- Material

- Metal

- Dimension (L*W*H)

- 132 x 235 x 313 Millimeter (mm)

SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Day

- Delivery Time

- 7 Days

About SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines

Competitive Edge and Application Surface

The SONODUR R leads with competitive advantage through automated UCI Leeb hardness testing, delivering fast and accurate results. Its usage spans various industrial surfaces from metals to coated components, maximizing efficiency on production lines. The device empowers factories with swift quality control, ensuring every component meets specifications. This high-tech solution enhances production output, reduces downtime, and is perfect for manufacturers seeking reliability across demanding applications.

Export Markets, Shipping, and Sample Policy

SONODUR R is exported via major FOB ports, extending its reach to global industrial markets. The primary export regions include Europe, Asia, and North America. Order processing is streamlined for timely delivery, and express shipping options accommodate urgent demands. Customers benefit from a fair sample policy, ensuring satisfaction prior to bulk purchase. The exchange procedure is simple and customer-oriented, demonstrating the manufacturers commitment to reliable service and customer confidence worldwide.

FAQs of SONODUR R - Automated UCI Leeb Hardness Testing For Production Lines:

Q: How does SONODUR R enhance industrial hardness testing?

A: SONODUR R utilizes automated UCI Leeb technology, providing rapid and precise hardness measurements directly on production lines. Its user-friendly setup integrates seamlessly into existing manufacturing processes, increasing operational efficiency.Q: What applications are suitable for SONODUR R?

A: SONODUR R is highly adaptable, ideal for metal and coated component surfaces across a wide range of industrial sectors, including automotive, aerospace, and heavy machinery production.Q: When can orders for SONODUR R be processed and shipped?

A: Orders are processed promptly upon confirmation, with express shipping options available to ensure that clients receive their equipment swiftly and securely.Q: Where does SONODUR R get exported from, and to which markets?

A: SONODUR R is exported from Germany through well-established FOB ports, reaching key markets in Europe, Asia, and North America.Q: What is the process for requesting samples or exchanges?

A: Interested customers can request samples under a transparent sample policy. Exchanges are managed through a straightforward process that prioritizes customer satisfaction and product integrity.Q: What benefits does the SONODUR R provide to manufacturers?

A: Manufacturers benefit from increased productivity, reduced downtime, superior testing accuracy, and compliance with quality standards, making it a valuable asset for production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hardness Tester Category

Sono H Hand-Held UCI Hardness Testing Probes

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Color : Silver

Usage : Industrial

Application : Industrial Hardness Testing

Power Supply : Battery operated

Sono M - Motorised UCI Hardness Measurement Probes

Minimum Order Quantity : 1 Unit

Material : Aluminium

Color : Silver

Usage : Industrial

Application : Industrial Metal Hardness Testing

Power Supply : Rechargeable Liion Battery / USB Supply

Sono l - Leeb Rebound Sensors

Minimum Order Quantity : 1 Unit

Material : Plastic

Color : Blue

Usage : Industrial

Application : Hardness Testing of Metallic Materials

Power Supply : Battery Operated

Sonodur 3 Portable Dynamic Hardness Testing Machines

Minimum Order Quantity : 1 Unit

Material : Metal

Color : Black

Usage : Industrial

Application : Industrial

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry