मलà¥à¤à¥à¤à¥à¤¨à¤² फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤¿à¤à¤ डिवाà¤à¤¸

MOQ : 1 Unit

मलà¥à¤à¥à¤à¥à¤¨à¤² फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤¿à¤à¤ डिवाà¤à¤¸ Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- टेलीग्राफिक ट्रांसफर (T/T), चेक

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मलà¥à¤à¥à¤à¥à¤¨à¤² फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤¿à¤à¤ डिवाà¤à¤¸

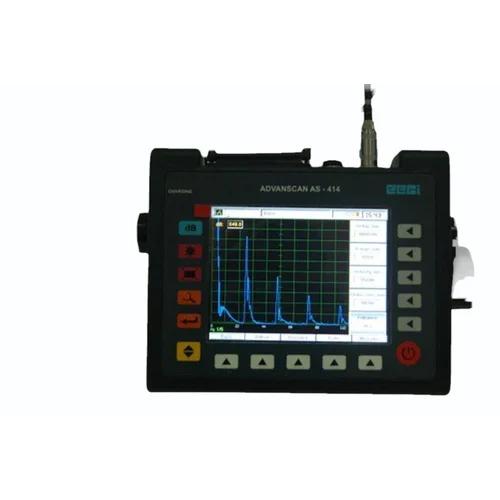

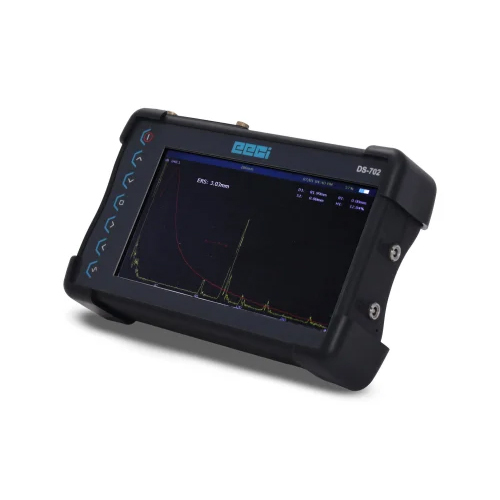

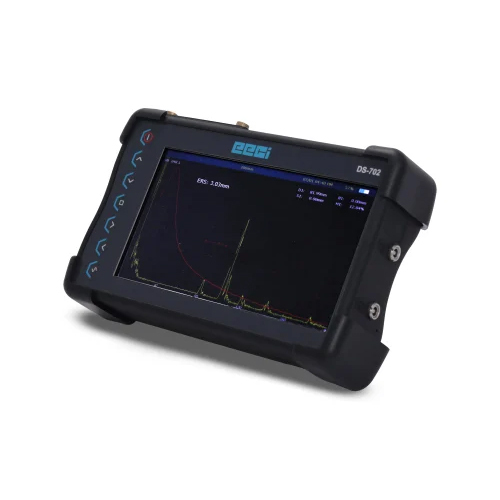

Designed for offering high speed testing, our offered Multichannel Flaw Detector is engineered with the integrator in mind to become the most preferred industrial detection component. The mentioned detector is considered as one of the instruments of the new generation. Potentialities of the rendered detector can be easily determined by the efficient sound of the tested material, software that supports all the functions, format in which the information is displayed to the operator and servicing functions of the Multichannel Flaw Detector. This instrument is highly demanded in the industrial sector because of the durability, versatility, flexibility and reliability it offers.

Applications of Multichannel Flaw Detector :

- Aerospace manufacturing

- Automobile industry

- Component testing

- Integrated inspection systems

- Welded components

Technical specification

Lock | Keyboard cab be Lock |

Digit Display | 2 Digit,3 Digit |

Warranty | 6 Months |

Auto Power Off | Yes |

Data Hold | Yes |

Low Battery Indication | Yes |

Receiver Bandwidth | 0.5 to 15MHz by Broad Band Amplifier |

Probe Connector | BNC Type |

Measurement Units | Millimeter |

Precision-Driven Laboratory Testing

This flaw detecting device is built to deliver reliable and detailed results for laboratory applications. Its metal construction provides durability, while the multichannel system allows for comprehensive scanning of a wide array of samples. The device ensures that even minute imperfections are efficiently identified, promoting high-quality standards.

Versatile Applications Across Industries

Ideal for manufacturers, exporters, suppliers, and traders, the device supports various laboratory routines across India. The black-finished metallic equipment is crafted to meet different industry requirements, ranging from research to product quality inspection, offering dependable performance during rigorous testing procedures.

FAQs of Multichannel Flaw Detecting Device:

Q: How does the Multichannel Flaw Detecting Device operate in the laboratory?

A: The device utilizes advanced multichannel technology to scan and identify flaws within material samples. By transmitting signals through the samples, it detects inconsistencies, enabling accurate assessment and quality control within lab environments.Q: What materials can be tested using this device?

A: This device is specially constructed for assessing metallic samples but can be adapted for use with other laboratory materials. Its robust mechanism makes it suitable for various testing needs, particularly in industrial and research sectors.Q: When should this flaw detecting device be used in laboratory processes?

A: It is best employed during the inspection and quality assurance phases, ensuring material integrity before further processing or product release. Regular use enhances the detection of faults early in the research or production cycle.Q: Where can the device be utilized within India?

A: The Multichannel Flaw Detecting Device is widely used in laboratories, manufacturing units, and quality control departments across India by exporters, manufacturers, suppliers, and traders.Q: What is the process of using the flaw detector?

A: To operate the device, place the sample into the designated scanning area, select the appropriate channel settings, and initiate the test. The device then analyzes the sample for any internal or surface flaws, providing detailed readings.Q: What are the benefits of using this device in laboratory environments?

A: The key benefits include precise flaw detection, enhanced testing speed, and improved reliability of laboratory results. Its sturdy metal build coupled with multichannel analysis supports consistent and repeatable findings for quality-critical applications.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Ultrasonic Flaw Detector Category

हमारे निर्यात देश: ईरान, यूएई, नाइजीरिया, ब्राजील और मेक्सिको।

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें