मलà¥à¤à¥ सà¥à¤à¥à¤¨ फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤°

MOQ : 1 Unit

मलà¥à¤à¥ सà¥à¤à¥à¤¨ फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- टेलीग्राफिक ट्रांसफर (T/T), चेक

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About मलà¥à¤à¥ सà¥à¤à¥à¤¨ फ़à¥à¤²à¥ डिà¤à¥à¤à¥à¤à¤°

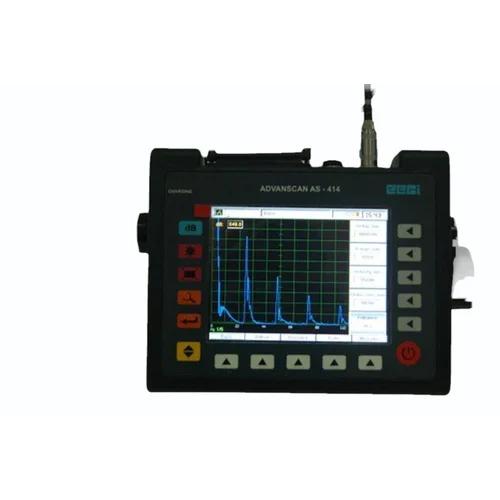

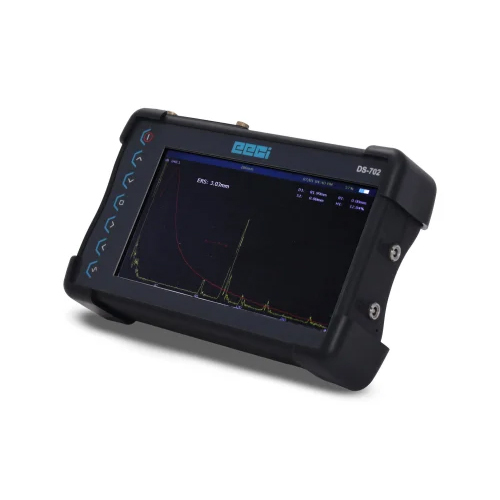

We are specialized in offering a precision engineered range of Multi Scan Flaw Detectors. Provided detectors are used for various flaw detection applications including crack detection, weld inspection, defect sizing and many more. Specially designed for laboratories, automotive, pipind and other manufacturing industries, these detectors are state-of-art productions. Available in several designs and technical specifications, proposed Multi Scan Flaw Detectors are offered at the most reasonable price to the clients.

Features:

- Longer service life

- Easy-to-Use

- Hand-held and compact design

- Quick and accurate results

Technical specification

Display | LCD |

Material | Plastic |

Frequency Range | 0.5-15 MHZ |

Features

- 8 individually programmable channels

- 4 digit 7 segment LED display to indicate Gain, Gate, Range, Memory etc.

- 9 sets of calibration Memory

Reliable Flaw Detection for Quality Assurance

Our Multi Scan Flaw Detectors provide accurate identification of material defects in plastic specimens. Featuring a wide test range and user-friendly design, these detectors are suitable for manufacturing, quality control, and research applications. Their compact build and lightweight nature (800 g) enable easy handling and transportation without compromising precision.

Versatile Applications Across Industries

Designed for multiple use cases, these flaw detectors are ideal for a broad array of industrial sectors such as plastics manufacturing, automotive component inspection, and laboratory testing. The flexible test range and adaptable voltage requirement ensure compatibility with standard laboratory and industrial settings across India and beyond.

FAQs of Multi Scan Flaw Detectors:

Q: How do Multi Scan Flaw Detectors operate on plastic specimens?

A: The detectors use advanced scanning technology to identify internal and surface defects in plastic materials. Simply place your 144.78 mm specimen in the device, select the appropriate test range (0-6000, 0-9999, or 0-25000 mm), and the system will scan and report flaws with high accuracy.Q: What benefits does this flaw detector offer to manufacturers and quality control teams?

A: The device enhances defect detection speed and accuracy, reduces inspection times, and improves overall product quality. Its broad test range and precise scanning make it suitable for various industrial and laboratory applications.Q: When should a Multi Scan Flaw Detector be used during the manufacturing process?

A: Flaw detectors are typically employed after initial fabrication and before final product assembly. Using them at this stage ensures that any potential defects in the plastic material are identified and addressed early, minimizing costly downstream issues.Q: Where can these flaw detectors be utilized effectively?

A: They are ideal for use in manufacturing plants, quality control laboratories, research institutions, and plastic component production facilities. Their adaptability and portability make them suitable for both on-site and off-site inspections.Q: What is the process for inspecting a specimen of 144.78 mm size?

A: Prepare the specimen and power the detector using a 220V supply. Place the specimen within the scanning area, set the required testing range, and initiate the scan. The detector will analyze and highlight any flaws for further assessment.Q: How does the export, manufacturing, and supply chain support benefit clients in India?

A: As an exporter, manufacturer, supplier, and trader in India, we provide timely delivery, after-sales support, and custom solutions, ensuring clients receive reliable products tailored to their operational needs.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in Ultrasonic Flaw Detector Category

हमारे निर्यात देश: ईरान, यूएई, नाइजीरिया, ब्राजील और मेक्सिको।

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें