Electrical Wedges

Electrical Wedges Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 4-8 Week

- Main Export Market(s)

- Central America, Eastern Europe, Middle East, South America, Western Europe, Australia, Asia, North America, Africa

- Main Domestic Market

- All India

About Electrical Wedges

Superior Stainless Steel Construction

Manufactured from premium stainless steel, our electrical wedges offer outstanding corrosion resistance and strength, vital for medical environments requiring strict hygiene and reliability. The silver finish not only ensures a clean appearance but also enhances durability against frequent use.

Optimized for Medical Equipment

Designed for seamless integration into medical machinery, these wedges support stable electrical connections at 220 volts. Their precise build quality supports accuracy and safety, directly contributing to the smooth operation of essential healthcare devices.

Trusted Supplier Across India

With a strong reputation as an exporter, manufacturer, supplier, and trader, we are committed to quality and a strong distribution network throughout India. Our expertise ensures tailored solutions, prompt service, and products that meet rigorous industry standards.

FAQs of Electrical Wedges:

Q: How are the electrical wedges used in medical machines?

A: Electrical wedges are incorporated into medical machines to ensure stable electrical connectivity and effective contact, contributing to the reliable performance and safe operation of the equipment.Q: What materials are these wedges made from, and why is this important?

A: These wedges are constructed from stainless steel (SS), which is essential for its durability, corrosion resistance, and compliance with medical standards for hygiene and longevity.Q: When should these electrical wedges be replaced or maintained?

A: Routine inspection during machine maintenance is recommended. Replacement is advised if there are signs of wear, corrosion, or loss of conductivity to maintain optimal machine safety and function.Q: Where are these electrical wedges manufactured and supplied from?

A: These electrical wedges are manufactured and supplied from India, available across the nation and exported to international markets, supported by a reliable supply chain.Q: What is the process for installing these wedges in a medical machine?

A: Installation involves securely fitting the wedge into the designated slot within the medical machine, ensuring proper alignment and connection to the electrical system for efficient conductivity.Q: What voltage do these wedges support, and why is it significant?

A: They are rated for use with 220 volts, matching the standard voltage requirements for most medical machines in India, thus assuring compatibility and safety for a range of devices.Q: What benefits do these electrical wedges provide to medical equipment?

A: They enhance equipment reliability, extend machine lifespan by ensuring consistent connectivity, and their stainless steel construction supports easy cleaning to meet medical hygiene standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Probes Category

Ultrasonic Probe and Accessories

Price Range 1000.00 - 5000.00 INR

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : White and Gold

Usage : For Industrial

Temperature : 1050 Celsius (oC)

Rail Tester Probes

Price Range 155000.00 - 355000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : SS

Color : Silver

Usage : For Medical

Ultrasonic Probes

Price Range 15000.00 - 55000.00 INR

Minimum Order Quantity : 1 Unit

Material : Metal

Color : Black and Silver

Usage : For Industry

Temperature : 050 Celsius (oC)

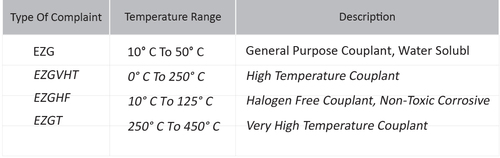

Ultrasonic Couplants

Price Range 51000.00 - 6500.00 INR

Minimum Order Quantity : 2 Tons

Material : Gel

Usage : Hospital,Laboratory,Clinic

Temperature : 160 Celsius (oC)

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry