Eddy Current For Surface Defects - Statograph Cm+/cm

Eddy Current For Surface Defects - Statograph Cm+/cm Specification

- Voltage

- 220 Volt (v)

- Usage

- Industrial

- Application

- Industrial

- Display Type

- Digital

- Temperature

- 50 Celsius (oC)

- Color

- Black

- Material

- Metal

- Operating Voltage

- 220 Volt (V)

- Product Type

- Eddy Current For Surface Defects - Statograph Cm+/cm

- Power Supply

- Electric

Eddy Current For Surface Defects - Statograph Cm+/cm Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 7 Days

About Eddy Current For Surface Defects - Statograph Cm+/cm

Compact and robust, the STATOGRAPH CM+ / CM consists of powerful hardware and software toguarantee reliable inspections. Both STATOGRAPH modules are network-compatible and can thus beoperated via a tablet or smartphone. Production line status can therefore be checked anytime andanywhere, meaning that immediate corrective action can be taken if necessary. Test parameters and othersettings can be captured and adjusted on the fly.The STATOGRAPH CM+ also has a touch screen for use directly in the line.

On the STATOGRAPH CM, a multi-color LED tells the device status with a quick glance into the control cabinet.

SENSOR TECHNOLOGY:

All existing probes can be connected as usual to the new STATOGRAPH CM+ / CM modules. A broad portfolio of standard and special-purpose probes is available. This means that, with FOERSTER, youre optimally prepared for any challenge.

Standard probes:For crack testing on components, stationary differential-eddy-current probes are usually installed directly in the test station. These have a very high test sensitivity and generate reproducible test results.

Special probes:Components with complex geometries require special test solutions. For this reason, FOERSTERs probe portfolio includes, among others, angled sensors and its FLEXPROBES, which are flexible probes that can be adapted to the unique geometry of the test piece.

In addition, we can also develop customer-specific probes for high-resolution testing.

Advanced Eddy Current Technology for Industrial Use

The Statograph CM+/CM employs state-of-the-art eddy current technology to detect even the smallest surface defects in metallic components. Designed for rigorous industrial environments, it ensures high accuracy and rapid throughput. Its digital display provides instant feedback, streamlining defect analysis and reporting for manufacturers, suppliers, and exporters.

Exceptional Durability and Convenience

Built from sturdy metal with a modern black finish, this equipment boasts a user-friendly design and can operate reliably at up to 50C. The 220V power supply ensures compatibility with most industrial electrical systems, while its straightforward operation makes it suitable for both seasoned technicians and new users.

FAQs of Eddy Current For Surface Defects - Statograph Cm+/cm:

Q: How does the Statograph CM+/CM detect surface defects?

A: The Statograph CM+/CM uses eddy current technology, which passes alternating electrical currents through a coil near the test objects surface. Variations in the electrical signal indicate the presence of surface defects such as cracks, pits, or inclusions.Q: What industries commonly use this eddy current tester?

A: This device is ideal for industrial sectors where precision surface inspection of metal parts is required, including automotive, aerospace, manufacturing, and metal fabrication industries.Q: When is the best time to use the Statograph CM+/CM in quality control processes?

A: It is best used during final inspection stages or routine maintenance checks to ensure components are free from surface defects before assembly or delivery, thereby enhancing product reliability.Q: Where can the Statograph CM+/CM be obtained?

A: You can acquire this product from exporters, manufacturers, suppliers, and traders specializing in industrial testing equipment. It is manufactured in Germany, ensuring exceptional quality.Q: What is the process for operating this eddy current tester?

A: Simply connect the device to a 220V power supply, set the appropriate test parameters using the digital display, and move the coil over the metal surface. The digital screen displays test results instantly, highlighting any detected defects.Q: How does using the Statograph CM+/CM benefit industrial users?

A: Utilizing this device ensures rapid, non-destructive detection of surface anomalies, boosts product quality, reduces the risk of failure in service, and minimizes inspection time, all contributing to efficient and cost-effective operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Eddy Current Component Testing Machine Category

Magnatest ECM - Eddy Current Material Mix Up Test Instrument

Minimum Order Quantity : 1 Unit

Color : White

Product Type : Magnatest ECM Eddy Current Material Mix Up Test Instrument

Usage : Industrial

Power Supply : 100240 V AC, 50/60 Hz

Material : Metal

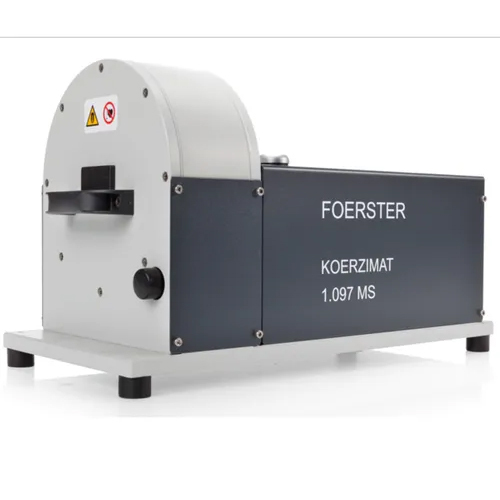

Koerzimat 1.097 MS For Measuring The Saturation Polarization Sigma-S And JS

Minimum Order Quantity : 1 Unit

Color : Black

Product Type : Koerzimat 1.097 MS For Measuring The Saturation Polarization SigmaS And JS

Usage : Industrial

Power Supply : 230 V / 5060 Hz

Material : Aluminum

Statograph Cm+/cm- Eddy Current Crack Tester

Minimum Order Quantity : 1 Unit

Color : Black

Product Type : Statograph Cm+/cm Eddy Current Crack Tester

Usage : Industrial

Power Supply : Electric

Material : Metal

Koerzimat 1.097 Hcj/J-h For Measurement Of Hard Metals testing, Coercivity, Hysteresis Loop

Minimum Order Quantity : 1 Unit

Color : Grey

Product Type : Koerzimat 1.097 Hcj/Jh For Measurement Of Hard Metals testing, Coercivity, Hysteresis Loop

Usage : Industrial

Power Supply : Electric

Material : Metal

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry