Circoflux Magnetic Flux Leakage Testing Solution

Circoflux Magnetic Flux Leakage Testing Solution Specification

- Voltage

- 220 Volt (v)

- Color

- White

- Power Supply

- Electric

- Material

- Metal

- Usage

- Industrial

- Product Type

- Circoflux Magnetic Flux Leakage Testing Solution

Circoflux Magnetic Flux Leakage Testing Solution Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 7-10 Days

About Circoflux Magnetic Flux Leakage Testing Solution

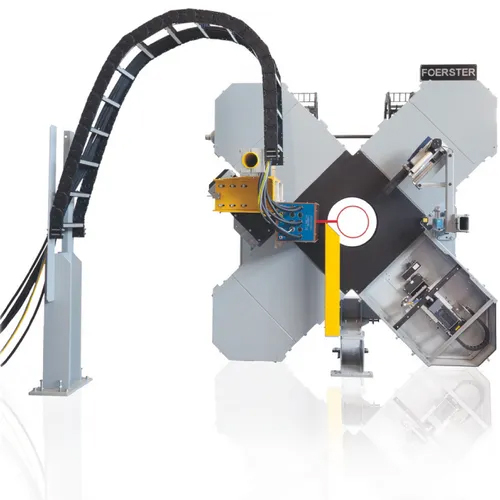

NON-DESTRUCTIVE CRACK TESTING WITH ROTATING PROBE

The CIRCOFLUX test system is used for the non-destructive surface testing of ferromagnetic steel bars using the magnetic flux leakage method in accordance with standard EN 10221. This method is the most sensitive surface testing method for longitudinal, crack-like defects in hot-rolled ferromagnetic steel bars. The CIRCOFLUX sensor system therefore replaces subjective testing methods such as the magnetic powder test (magnetic crack detection) and visual checks, which are difficult to document and reproduce.

The available sensor systems cover a material diameter range from approx. 10 to 180 mm. FOERSTERs long-standing experience in this field ensures high operating reliability. The modular design of the test electronics is also ideally suited to meet future demand for ever increasing defect detection sensitivity.

Your advantages at a glance- Standardized hardware and software for all FOERSTER test instruments simplifies the handling

- Easy operation using modern touchscreen display

- Network integration in existing production and quality systems

- Integrated diagnostic and documentation function for compiling your test results

- Relational database for high data integrity and open port to other applications

- Maximum detection sensitivity of defects from 0.1 mm depth on ferromagnetic rods with hot-rolled surface

- Test material diameter from 10 - 180 mm

- Pivoting test levers also tolerate non-straight material and protect against damage to or destruction of the test elements

- Central adjustment to the test diameter minimizes the risk of adjustment errors

- Automatic dimensions adjustment reduces setting up time and increases productivity

|

Sensor system: |

Rotating sensor system with two opposite test heads |

|

Max. number of measurement channels: |

24 |

|

Max. throughput speed: |

4 m/s |

|

Magnetizing current frequency: |

6 kHz (Ro75, Ro100, Ro180) or 7.5 kHz (Ro130) |

|

Testing error: |

depth 0.15 mm x width 0.1 mm |

|

Diameter ranges: |

10 - 75 mm (Ro 75); 10 - 100 mm and 15 - 105 mm (Ro 100); 15 - 130 mm (Ro 130); 20 - 180 mm (Ro 180) |

|

Setting time (with roller guide): |

approx. 3 minutes (Ro 75, Ro 100, Ro 130); approx. 5 minutes (Ro 180) |

|

Maximum rotational speeds: |

2,400 rpm (Ro 75); 1,500 rpm (Ro 100 and Ro 130); 960 rpm (Ro 180) |

|

Maximum throughput speed: |

2 m/s (Ro 75); 3.75 m/s (Ro 100); 4 m/s (Ro 130); 2.4 m/s (Ro 180) |

Advanced Industrial Testing

Circoflux ensures reliable non-destructive testing for diverse industrial environments. Its magnetic flux leakage technology allows users to identify cracks, corrosion, and other structural flaws in metal components swiftly, improving maintenance efficiency and operational safety.

Powerful and Efficient Performance

Running on a standard 220 Volt electric supply, Circoflux delivers consistent and accurate results. The durable metal construction stands up to rigorous use while its user-friendly design accelerates the detection process, lowering downtime and minimizing failure risks.

FAQs of Circoflux Magnetic Flux Leakage Testing Solution:

Q: How does the Circoflux Magnetic Flux Leakage Testing Solution operate in industrial environments?

A: The Circoflux system works by detecting disruptions in the magnetic flux field caused by defects such as cracks or corrosion in ferromagnetic materials. Connect it to a 220 Volt electric power source and apply it to the area under inspection; the device then highlights leakage spots, indicating potential areas of concern.Q: What types of industrial applications is this testing solution suitable for?

A: This solution is ideal for use in power plants, manufacturing units, heavy machinery service centers, and other industrial sectors that require non-destructive evaluation of metal structures for safety and maintenance.Q: When should you use magnetic flux leakage testing in your maintenance schedule?

A: You should utilize magnetic flux leakage testing during routine inspections, before critical operations, and when there are visible signs of wear or corrosion, ensuring early detection of faults and preventing costly downtime.Q: Where can the Circoflux Magnetic Flux Leakage Solution be sourced in India?

A: You can purchase the Circoflux solution from authorized exporters, manufacturers, suppliers, and traders across India. It is readily available to meet industrial quality assurance and safety needs.Q: What are the primary benefits of using the Circoflux solution for defect detection?

A: Using Circoflux boosts safety by identifying hidden flaws before they escalate. It streamlines the inspection process, delivers precise results, and helps extend the lifespan of metal components, ultimately saving operational costs.Q: What is the process for conducting a magnetic flux leakage test with Circoflux?

A: First, connect the device to a 220 Volt electric supply. Then, position it over the area to be inspected. The Circoflux sensor detects any interruptions in the magnetic field, helping operators locate and assess imperfections without damaging the material.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Eddy Current Semi-Finished Material TestingMachine Category

Defectovision Ir Inductive Heat Flux Thermography For Testing Tubes Billets Rails And Profiles

Minimum Order Quantity : 1 Unit

Temperature : 10C to 45C operating range

Material : Metal

Color : White

Product Type : Defectovision Ir Inductive Heat Flux Thermography For Testing Tubes Billets Rails And Profiles

Power Supply : 230V AC, 50/60 Hz

Defectomat DA Eddy Current Testing Solution

Minimum Order Quantity : 1 Unit

Temperature : Operating: 0C to +50C

Material : Metal

Color : White

Product Type : Defectomat DA Eddy Current Testing Solution

Power Supply : 230 V AC, 50/60 Hz

Circograph CI Eddy Current Crack Detection System

Minimum Order Quantity : 1 Unit

Temperature : 10C 40C

Material : Metal

Color : White

Product Type : Circograph CI Eddy Current Crack Detection System

Power Supply : 230V AC, 50 Hz

Defectomat ECM Eddy Current Tester

Minimum Order Quantity : 1 Unit

Temperature : 5C to 45C

Material : Metal

Color : White

Product Type : Defectomat ECM Eddy Current Tester

Power Supply : Electric

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry